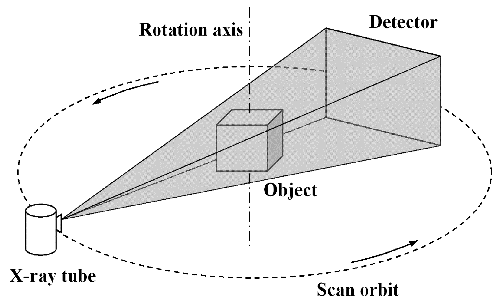

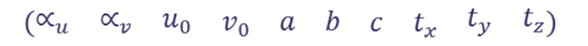

3D X-RAY TOMOGRAPHY

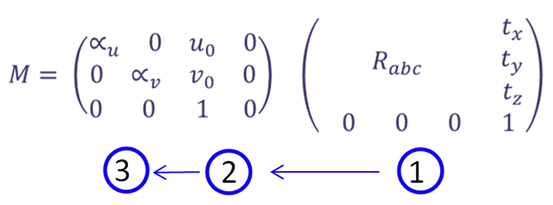

GEOMETRIC CALIBRATION

In short

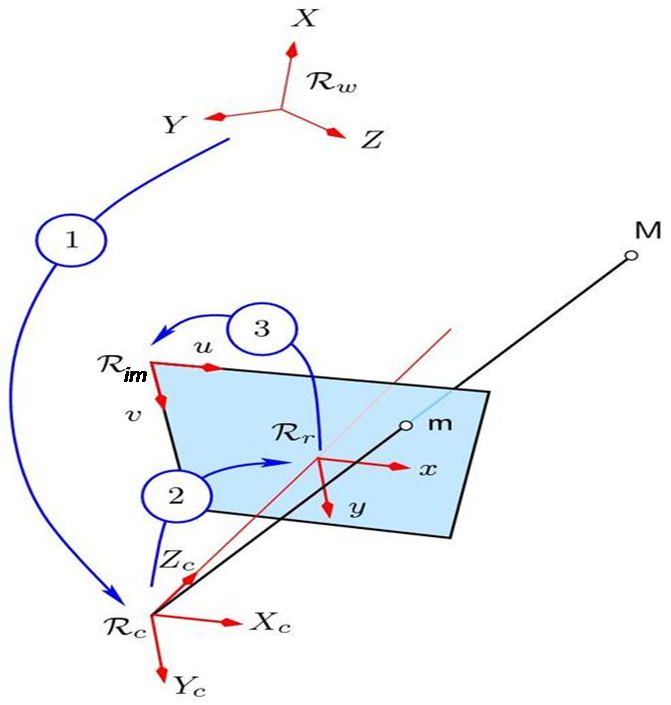

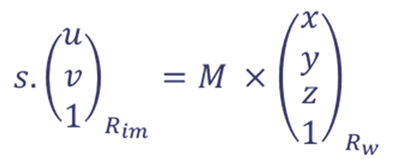

This project was my final year internship at Thales Electron Devices. I was responsible of the whole development of a calibration module for 3D X-Ray tomography platform. The challenge was to have to most efficient and accurate calibration, to be able to have the best possible results for 3D recontruction. This was a complex and complete project as I had to do many different things, such as:

- Mathematical Modeling, Linear Algebra and Spatial geometry

- Computer Vision and Image Processing

- Numerical Optimisation

- Software R&D and parallel programming

Technologies used: C++, Boost Library, OpenCV, Qt, OpenMP, SVN.